Aws Cwi - Questions

Aws Cwi - Questions

Blog Article

The Greatest Guide To Aws Cwi

Table of ContentsAws Cwi Things To Know Before You BuyAws Cwi Things To Know Before You BuyExcitement About Aws CwiFascination About Aws CwiFascination About Aws Cwi

Third-party quality assurance evaluation of steel fabrication fixate welding inspection, as well as assessment of bolting and painting of architectural steel. KTA's steel examiners provide Top quality Control (QC) assessors to supplement fabricator's/ service provider's internal QC personnel and on tasks that mandate retaining the solutions of a qualified assessor (e.g., CWI) utilized by an independent inspection company.Assessors carry out aesthetic assessments of material for uniformity with the accepted requirements, strategies and codes, as well as confirmation of Certified Material Examination Records (CMTR) for products used. Materials and elements are observed at key points along the production process in both steel mills and steel fabrication stores. KTA's qualified welding inspectors also witness welder and welding treatment certification tests as relevant to the extent of the job.

Steel manufacture inspection solutions additionally regularly consist of doing non-destructive screening (NDT), additionally called non-destructive examination (NDE), including Magnetic Fragment Checking (MT), Ultrasonic Testing (UT) and Liquid Penetrant Examining (PT) (AWS CWI). Inspections take area in steel mills and manufacture shops throughout the USA and on-site in the area and consist of all varieties of structures consisting of bridges, arenas, buildings, towers, posts, and sign structures

Some Of Aws Cwi

KTA provides assessment services for the fabrication of bridge girders, bearings, grid deck, indicator structures, light and traffic posts, pedestrian bridges, and various other highway elements. KTA also gives these services for construction of architectural steel for buildings, storage tanks and pipes. KTA's assessment services consist of finish inspections covering surface area prep work, paint, galvanizing, and metalizing.

KTA's ideology is to respond quickly to customers' requirements, match the best inspector to the job, and supply the requisite documentation. KTA has the support workers to provide technical consulting to the area workers and to the client. KTA has professionals readily available to speak with on welding, NDT and coatings.

Come join an incredible group in an exciting, rapid paced, and ever-growing industry! We are looking for a CWI's and/or NDT Level II accredited Welding Inspectors from in and around the Lithia Springs, GA area!

Get This Report about Aws Cwi

Suitable candidate will certainly have high pureness piping evaluation experience. CWI's and NDT Level II's extremely encouraged to use.

Pro QC's third-party welding inspection services include: Document Review Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Screening (NDT) Others Our welding assessment reports are provided within 24 hr and document all evaluation points appropriate to top quality, consisting of all determined weld blemishes and digital photos (Welding Inspection Agency) (https://www.pearltrees.com/awscw1w3lding#item647532147). Pro QC's team of examiners provides third-party welding inspections around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the UK, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the United States, Mexico, copyright, Brazil, Peru, and much more countries

Inspection of the welding work is important for correct high quality When your company is taking care of significant tasks with demands for third celebration independent welding evaluation, we offer exceptional welding witness evaluation services to validate that welding has actually been carried out according to many used welding criteria and specs. AQSS performs welding assessment services for clients from a range of markets.

The Main Principles Of Aws Cwi

Not adhering to effectively certified welding treatments frequently causes a weld of poor quality, which can boost the construction's possibility of failure under designated solution conditions. By checking for problems, our examiners can aid clients ensure that their welds satisfy relevant standards of quality control (AWS CWI). Weld inspections are conducted for several factors, the most typical of which is to determine whether the weld is of appropriate high quality for its designated application

Our welding examiners have the needed qualifications with years of experience with assessment and are acquainted with many used welding standards and requirements. AQSS has CWI accredited assessors.

The Greatest Guide To Aws Cwi

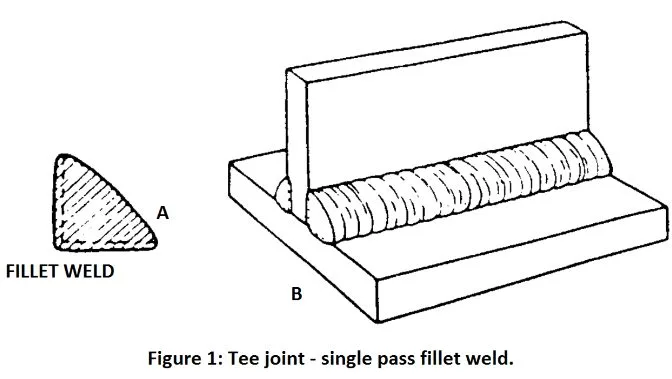

Weld inspection of laser and electron beam welded components usually complies with 3 distinctive courses: aesthetic evaluation; destructive screening; and non-destructive testing (NDT). includes looking at a weld with the naked eye and/or with some level of zoom. Normally, our examiners are looking for cracks, pits, surface area pores, undercut, underfill, missed out on joints, and other elements of the weld.

Examples can likewise be taken at periods throughout the manufacturing process or at the end of the run. Harmful testing samples are exactly reduced, machined, ground, and polished to a mirror-like coating. An acid etch is then put on visually bring out the weld, and the example is then examined under a microscope.

Report this page